Mercedes glass sensor calibration is a critical aspect of modern automotive care, requiring technicians to meticulously adjust sensors for precise measurements and data transmission, integral to ADAS, safety features, and vehicle performance. Effective training equips technicians with the knowledge and skills to understand theoretical principles, practice on various Mercedes models, identify issues, and troubleshoot problems. Skilled technicians are vital for vehicle safety, performance, and complex repair services, ensuring accurate calibration, preventing costly issues, and enhancing system efficiency across different car models.

The precision and reliability of modern vehicle systems, like those found in Mercedes cars, heavily rely on accurate glass sensor calibration. Central to this process is technician training, which plays a pivotal role in ensuring optimal performance. This article explores the fundamental aspects of Mercedes glass sensor calibration, delving into the key components of effective technician training and its real-world applications, ultimately highlighting the benefits of well-trained professionals in maintaining and enhancing these advanced systems.

- Understanding Mercedes Glass Sensor Calibration: The Basis of Technician Training

- Key Components of Effective Technician Training for Glass Sensor Calibration

- Real-World Applications and Benefits of Well-Trained Technicians in Mercedes Glass Sensor Calibration

Understanding Mercedes Glass Sensor Calibration: The Basis of Technician Training

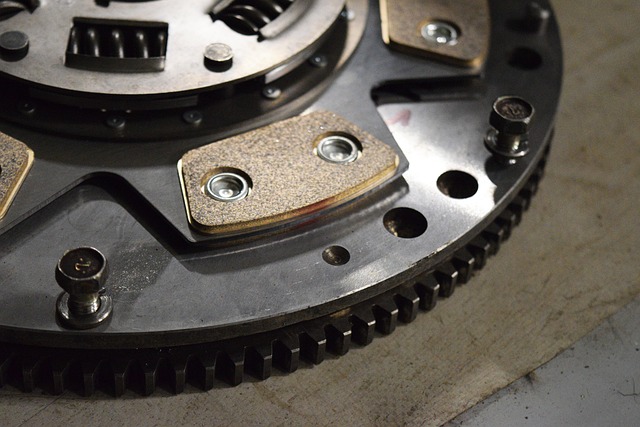

Mercedes glass sensor calibration is a critical process that forms the backbone of technician training in modern automotive care. It involves meticulously adjusting and fine-tuning sensors within a vehicle’s windshield or windows to ensure precise measurements and data transmission. This meticulous task demands a deep understanding of how these sensors work, their intricate connections with the car’s systems, and the precision required for accurate calibration.

Technicians undergoing training learn to navigate the complex landscape of Mercedes glass sensor calibration, which is integral to various functions like advanced driver-assistance systems (ADAS), safety features, and overall vehicle performance. The process involves more than just fixing; it encompasses enhancing and ensuring the integrity of these sensors, thereby contributing to a smoother, safer driving experience. This training equips technicians with the skills needed to offer top-notch collision repair services and address any car damage repair issues related to these sophisticated glass sensors.

Key Components of Effective Technician Training for Glass Sensor Calibration

Effective technician training is the cornerstone of precise Mercedes glass sensor calibration. It encompasses several key components that ensure technicians are equipped to handle the intricate processes involved. Firstly, comprehensive training should cover the theoretical principles behind glass sensor functionality, allowing technicians to understand the underlying technology and its sensitivity to environmental factors. This knowledge enables them to interpret sensor readings accurately.

Secondly, hands-on practice with a variety of Mercedes models and their respective sensors is vital. Training sessions should simulate real-world scenarios, including teaching techniques for adjusting calibration settings, identifying potential issues, and troubleshooting common problems encountered in auto repair shops or car collision repairs. Furthermore, exposure to different types of glass sensors and their unique characteristics equips technicians to select the right approach for each vehicle, ensuring optimal results for all auto body services provided.

Real-World Applications and Benefits of Well-Trained Technicians in Mercedes Glass Sensor Calibration

In the realm of modern automotive repair, Mercedes glass sensor calibration plays a pivotal role in ensuring optimal vehicle performance and safety. Well-trained technicians are the unsung heroes behind this process, meticulously adjusting sensors to exact specifications. Their expertise is not limited to Mercedes glass sensor calibration; it extends to various real-world applications, including meticulous automotive repair and intricate vehicle restoration. These skilled professionals possess a deep understanding of car systems, enabling them to pinpoint and rectify issues that might otherwise go unnoticed.

The benefits of their training are far-reaching. Accurate calibration ensures sensors function seamlessly with the vehicle’s computer, enhancing overall efficiency. This precision is crucial in preventing common problems like faulty speed readings or misjudged distance, which can be costly to repair, especially in cases of severe car scratch repair. Moreover, well-trained technicians can adapt their skills to a wide range of makes and models, making them invaluable assets in workshops across the industry.

The calibration of Mercedes glass sensors is a critical process that relies heavily on well-structured technician training. By equipping technicians with comprehensive knowledge and practical skills, organizations can ensure precise and reliable sensor performance. Effective training programs, as highlighted in this article, focus on key components such as theoretical understanding, hands-on experience, and continuous learning. The benefits are clear: improved accuracy, reduced errors, and enhanced customer satisfaction, ultimately elevating the overall quality of Mercedes glass sensor calibration.